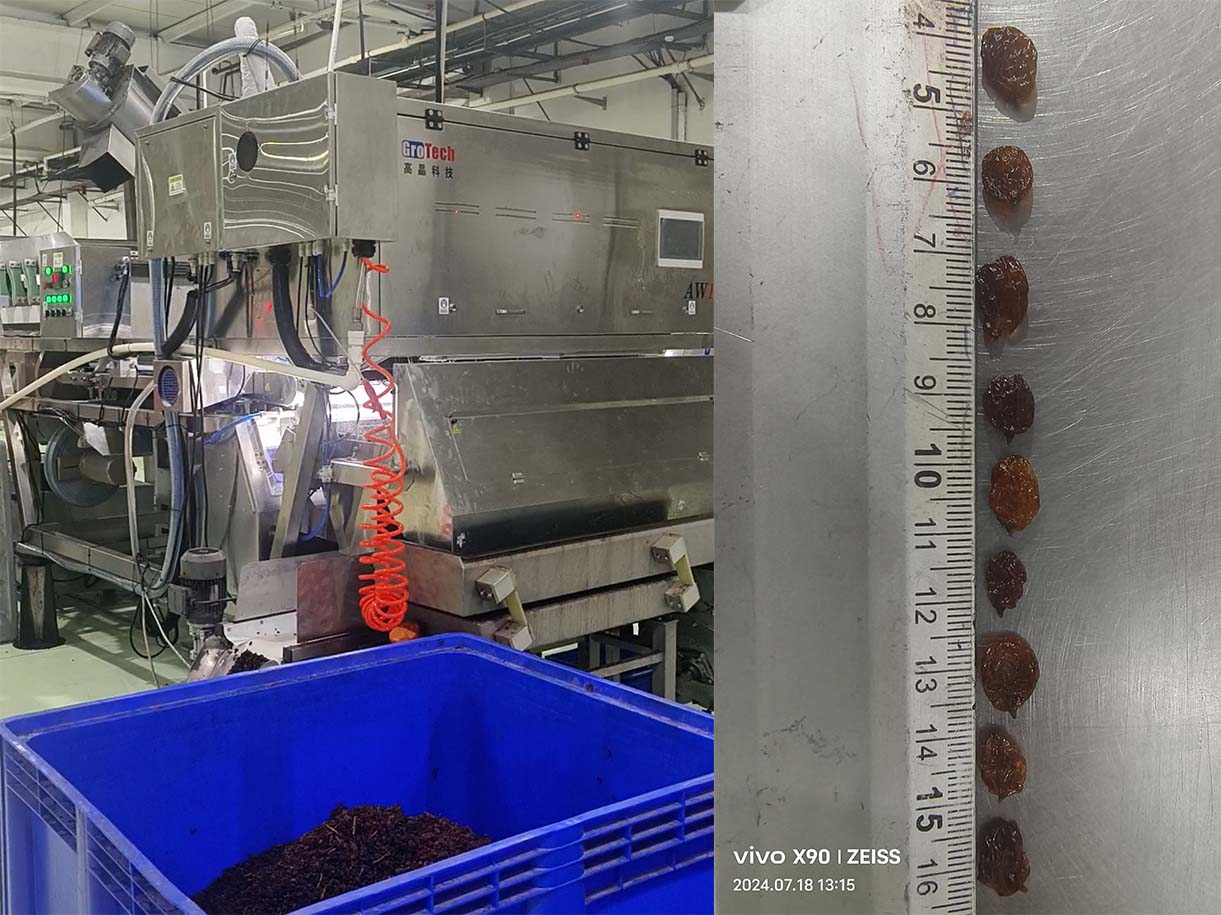

As consumer demands for food safety and quality continue to rise, the production of dried fruits such as raisins increasingly relies on efficient and precise automated equipment. GroTech’s AI Color sorting machine, It ensures efficient and accurate sorting, enhancing raisin quality by removing mold, spoilage, and foreign objects, thereby improving both food safety and market competitiveness.

Challenges in Raisin Sorting

During processing, raisins often develop color variations, mold, insect damage, and impurities due to environmental factors such as weather, storage conditions, and transportation. Traditional sorting methods rely heavily on manual labor, which, despite completing the task to some extent, are inefficient and prone to human error. This makes large-scale standardized production difficult.

Therefore, the industry faces a critical challenge: integrating intelligent equipment capable of efficient and precise sorting into raisin production.

GroTech's AI Color Sorting Machine Solution

GroTech’s AI color sorting machine combines artificial intelligence algorithms with high-precision image recognition technology to identify defects such as color differences, blemishes, mold, and foreign objects on raisins, thereby automatically rejecting substandard products. Key advantages include:

(1)High-Precision Color Recognition

The AI sorting machine uses multispectral image sensors to detect subtle color differences on raisins, including mold, spoilage, or moisture damage. IThese imperfections, often invisible to the naked eye, are accurately identified and removed, ensuring uniform color across batches.

(2)Intelligent Removal of Mold and Foreign Objects

Using deep learning algorithms, the AI sorting machine can recognize mold spots, insect damage, or foreign objects on the surface of raisins. These non-compliant raisins are efficiently removed, ensuring only high-quality products enter the market, safeguarding consumer health and safety.

(3)Automated High-Speed Processing

The AI sorting machine enables full automation of raisin production lines. It performs real-time detection and processing during high-speed operations, dramatically boosting efficiency while maintaining consistent quality.

(4)Enhancing Product Appearance and Market Competitiveness

Since raisin appearance significantly influences consumer purchasing decisions, the machine ensures uniformity in size, shape, and color. This elevates the product’s visual appeal, aligning with market demands for high-quality food and strengthening brand competitiveness.

Technical Advantages of the AI Color Sorting Machine

(1) Deep Learning Algorithms

GroTech’s AI sorting machine employs deep learning technology, enabling the system to autonomously learn and optimize sorting strategies. By continuously accumulating production data, the system adjusts to different materials and production environments, improving sorting efficiency.

(2)High-Speed and High-Precision

Equipped with high-speed cameras and processing units, the sorting machine captures and processes images of each raisin in real time. This combination of speed and accuracy ensures even minute defects are detected.

(3)Remote Monitoring and Data Analysis

With cloud computing and big data analysis, users can monitor the sorting machine’s performance in real time and adjust production parameters accordingly. Data analysis also provides insights into production quality trends, enabling further optimization of production management.

(4)Reduced Labor Costs and Increased Efficiency

Compared to manual sorting, the AI solution minimizes labor dependency, reducing costs while increasing throughput. Its high-volume processing capability ensures seamless large-scale production

Application Examples

GroTech’s AI color sorting machine has been widely adopted by raisin producers. For example, a leading manufacturer reported improved product consistency and appearance after implementation. The machine’s ability to detect contaminants also increased pass rates, bolstering brand trust.